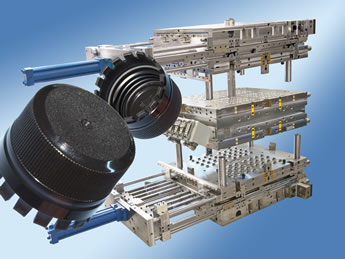

When a molded piece contains threads that are too aggressive to strip, a mechanical unscrewing mechanism is required to unscrew and eject the part. The most common way to achieve this is with a hydraulic cylinder mounted on a super structure. The piston pushes racks down through the mold. These racks interface with gears on the cores and, along with a set of bearings, allow the cores to turn and unscrew from the part while it is ejecting. Another similar solution is to utilize a power screw. The cores have a high helical thread cut into them and a plate with a ‘nut’ moves forward forcing the core to spin.

When a molded piece contains threads that are too aggressive to strip, a mechanical unscrewing mechanism is required to unscrew and eject the part. The most common way to achieve this is with a hydraulic cylinder mounted on a super structure. The piston pushes racks down through the mold. These racks interface with gears on the cores and, along with a set of bearings, allow the cores to turn and unscrew from the part while it is ejecting. Another similar solution is to utilize a power screw. The cores have a high helical thread cut into them and a plate with a ‘nut’ moves forward forcing the core to spin.